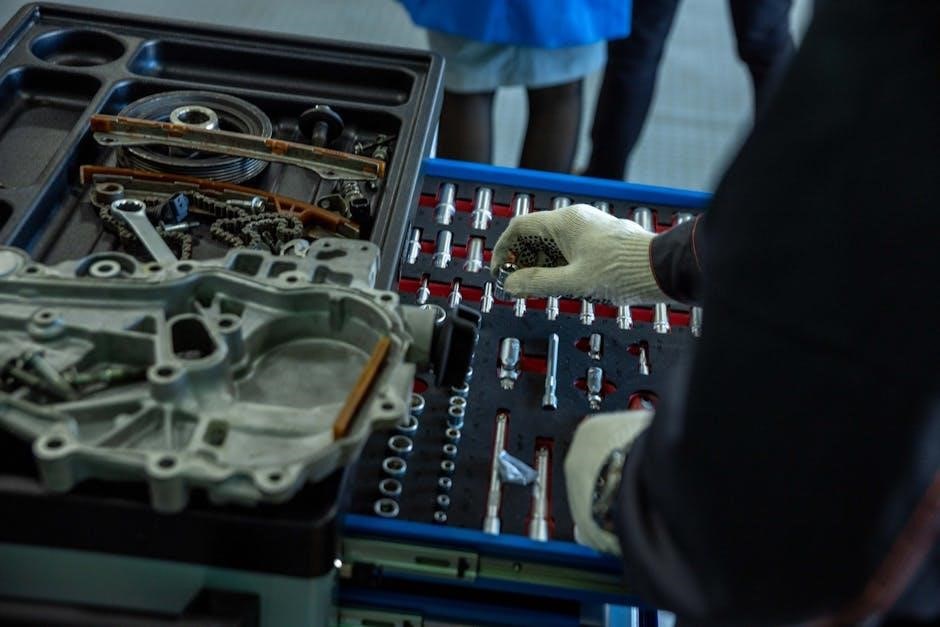

A manual transmission parts diagram illustrates the system’s components, including gears, shafts, and synchronizers. Understanding these elements is essential for effective maintenance and repair.

1.1 Overview of Manual Transmission

A manual transmission is a driver-operated gearbox that enables vehicle speed adjustment by manually changing gears. It consists of gears, shafts, and synchronizers, requiring clutch engagement for smooth shifting. This system offers reliability, fuel efficiency, and cost-effectiveness compared to automatic transmissions. Understanding its operation is crucial for maintenance, as it allows drivers to identify and address issues early, ensuring optimal performance and longevity of the vehicle.

1.2 Importance of Understanding Transmission Components

Understanding manual transmission components is vital for diagnosing issues early, preventing costly repairs, and ensuring smooth operation. Recognizing symptoms like gear wear or fluid leaks enables timely interventions. This knowledge empowers drivers to perform routine maintenance, such as checking fluid levels and inspecting seals, and makes troubleshooting more efficient. Familiarity with the system also enhances the ability to communicate with mechanics, ensuring accurate repairs and extending the lifespan of the transmission.

Key Components of a Manual Transmission

The key components of a manual transmission include gears, gear shafts, the clutch system, synchronizers, bearings, seals, and the transmission housing, each playing a crucial role in operation.

2.1 Gears and Gear Shafts

Gears and gear shafts are fundamental components of a manual transmission, enabling the vehicle to change speed and torque. Gears mesh together to provide different gear ratios, while shafts support and align them. Spur and helical gears are commonly used, with helical gears offering smoother operation. Gear shafts are typically made of high-strength materials like steel for durability; Proper lubrication is essential to prevent wear and ensure smooth gear engagement. Misaligned or worn gears can lead to noisy operation and reduced performance.

2.2 Clutch System

The clutch system is a critical component of a manual transmission, enabling the driver to engage and disengage the engine from the transmission. It includes the clutch pedal, master and slave cylinders, clutch disc, and pressure plate. When the clutch pedal is pressed, it disengages the engine, allowing smooth gear shifts. Hydraulic or cable-actuated systems operate the clutch, requiring proper fluid levels and maintenance to ensure reliable performance. Over time, the clutch disc can wear out, necessitating replacement for continued functionality.

2.3 Synchronizers

Synchronizers are essential for smooth gear shifting in a manual transmission. They align the rotational speed of the gear with the shaft, ensuring seamless engagement. The synchronizer assembly includes a hub, sleeve, and rings that engage gears. When worn, synchronizers can cause grinding or difficulty shifting gears. Proper lubrication and maintenance are crucial to extend their lifespan and maintain optimal shifting performance; Regular inspection helps identify worn components early, preventing costly repairs.

2.4 Bearings and Seals

Bearings and seals are critical for reducing friction and preventing fluid leaks in the manual transmission. Bearings support gear shafts, ensuring smooth operation, while seals protect internal components from contamination. Over time, bearings can wear out, and seals may crack, leading to leaks and damage. Regular inspection and replacement of these parts are essential to maintain the transmission’s efficiency and prevent costly repairs. Proper lubrication also extends their lifespan.

2.5 Transmission Housing

The transmission housing is the outer casing that encloses and protects the internal components of the manual transmission. Typically made of durable materials like aluminum or steel, it provides structural support and ensures proper alignment of gears and shafts. The housing also acts as a reservoir for transmission fluid, which lubricates the moving parts. Inspecting the housing for cracks or leaks is crucial to prevent damage and maintain optimal performance and reliability over time.

Working Principle of a Manual Transmission

A manual transmission operates by engaging gears through driver input via the clutch and gearshift. The clutch disconnects engine power, while synchronizers align gear speeds for smooth shifts, enabling efficient power transfer to the wheels.

3.1 Power Flow Through the Transmission

Power flows from the engine to the transmission via the input shaft. The clutch disengages engine power during gear shifts. When a gear is selected, the synchronizer aligns shaft speeds, engaging the desired gear. The transmission then transfers power through gearsets and bearings to the output shaft, ultimately delivering torque to the driveshaft and wheels. This precise mechanical process ensures efficient energy transfer, controlled by the driver’s gearshift and clutch operation.

3.2 Role of the Clutch in Gear Shifting

The clutch plays a pivotal role in gear shifting by temporarily disconnecting the engine from the transmission. When the driver presses the clutch pedal, it disengages the engine’s power, allowing smooth gear transitions without grinding. This mechanism prevents damage to gears and ensures precise control over shifting. The clutch enables the driver to manually select gears, making it essential for smooth and efficient operation of the manual transmission system.

3.3 Function of Synchronizers in Smooth Shifting

Synchronizers ensure smooth gear shifting by aligning the rotational speed of the gear with the shaft before meshing. This prevents grinding and allows seamless transitions between gears. The synchronizer ring engages with the gear, synchronizing their speeds using friction surfaces. This mechanism reduces wear and tear on components, enabling precise and efficient shifting. Proper synchronizer function is crucial for maintaining smooth and controlled gear changes in manual transmissions.

Common Issues in Manual Transmission Parts

Manual transmissions often face issues like worn gears, leaks, and clutch wear. Symptoms include unusual noises, difficulty shifting, and fluid leaks, requiring prompt inspection and repair.

4.1 Symptoms of Worn or Damaged Gears

Worn gears in a manual transmission often cause grinding noises during shifts. A crunching sound in lower gears indicates worn gear teeth. Hesitation or jerking during acceleration signals gear wear. Gears may pop out of position, leading to loss of power. Increased shifting effort can signal worn gears, affecting smooth engagement. These symptoms stress the importance of consulting a parts diagram. Early detection helps prevent further damage to gear shafts and synchronizers.

4.2 Leaks and Seals Failure

Leaks in a manual transmission often result from worn or damaged seals. Common signs include fluid dripping from the transmission housing or bellhousing. Contaminated fluid can degrade internal components. Ignoring leaks leads to premature wear of gears and bearings. Inspecting seals regularly is crucial to prevent costly repairs. Replacing seals promptly ensures optimal performance and prevents further damage to the transmission system.

4;3 Clutch Wear and Replacement

Clutch wear is common in manual transmissions due to frequent engagement and disengagement. Symptoms include slipping, difficulty shifting gears, and a spongy pedal feel. Over time, the clutch disc and pressure plate wear out, requiring replacement. Ignoring these issues can lead to costly repairs. Regular inspection of the clutch system is essential to ensure smooth operation and prevent premature failure. Prompt replacement extends the transmission’s lifespan and maintains performance.

Maintenance and Repair Tips

Regular fluid checks and inspections for leaks or wear are crucial. Replacing worn parts promptly ensures smooth operation and prevents costly repairs. Proper maintenance extends longevity.

5.1 Checking Transmission Fluid Levels

Regularly checking transmission fluid levels is vital for maintaining smooth operation. Low or degraded fluid can cause gear shifting issues and damage components. Use the dipstick to measure levels, ensuring it’s between the recommended marks. Check for fluid color and consistency; dark or gritty fluid indicates contamination. Top up with the correct type if needed, and address any leaks promptly to prevent further damage and ensure optimal performance.

5.2 Inspecting for External Damage

Regular inspections of the manual transmission’s exterior can prevent major repairs. Look for signs of leaks, dents, or rust on the housing and components. Check the seals and gaskets for wear or damage, as these can lead to fluid leaks and contamination. Ensure all bolts and connections are secure. If damage is found, clean the area thoroughly and address the issue promptly to maintain optimal performance and prevent further deterioration.

5.3 Replacing Worn Parts

Replacing worn parts in a manual transmission is crucial for maintaining performance. Identify components like gears, bearings, or synchronizers that show excessive wear. Use specialized tools to remove and install new parts, ensuring proper alignment and lubrication. Replace seals and gaskets to prevent leaks. Clean the transmission thoroughly before reassembly to avoid contamination. Addressing worn parts promptly prevents further damage and ensures smooth operation, reducing the risk of costly repairs down the line.

Advantages of Manual Transmission

Manual transmissions offer improved fuel efficiency, lower repair costs, and a more engaging driving experience. They provide better control over gear shifts, enhancing performance and driver satisfaction.

6.1 Fuel Efficiency

Manual transmissions typically offer better fuel efficiency compared to automatics due to fewer mechanical components and no torque converter. This results in less energy loss, especially in city driving or hilly terrain. Drivers can optimize gear shifts to maximize mileage, making manuals a cost-effective choice for those prioritizing fuel economy. Over time, this efficiency translates to significant savings on fuel costs, enhancing the overall value of owning a manual transmission vehicle.

6.2 Cost-Effectiveness

Manual transmissions are generally more cost-effective than automatics due to fewer complex components and lower production costs. They require less maintenance over time, as they have no torque converter or hydraulic systems. This simplicity reduces repair expenses and extends the lifespan of the transmission. Additionally, manual transmissions are often more durable, leading to long-term savings for drivers who prioritize affordability and reliability in their vehicles.

6.3 Driving Experience

Manual transmissions offer a more engaging and interactive driving experience, allowing drivers to feel connected to their vehicle. Shifting gears manually provides a sense of control and precision, making every drive more enjoyable. This hands-on approach fosters a deeper connection between the driver and the car, creating a more satisfying and dynamic experience behind the wheel.

DIY Manual Transmission Projects

DIY manual transmission projects involve rebuilding, upgrading, or customizing components like gears and synchronizers to enhance performance or fix issues, requiring mechanical skills and precision.

7.1 Rebuilding a Manual Transmission

Rebuilding a manual transmission involves disassembling, inspecting, and replacing worn or damaged components like gears, bearings, and synchronizers. Proper tools and mechanical skills are essential. Start by draining the transmission fluid and removing the housing. Inspect each part for wear, replacing as needed. Reassemble carefully, ensuring all components are aligned and lubricated. This process restores performance and extends the transmission’s lifespan, requiring patience and precision.

7.2 Upgrading Transmission Components

Upgrading transmission components enhances performance and durability. Common upgrades include installing high-performance gears, bearings, and synchronizers. These improvements can increase torque capacity and smooth shifting. When upgrading, ensure compatibility with existing parts. Proper installation and alignment are crucial to maintain optimal functionality. Upgrading transmission components is a cost-effective way to enhance driving experience and extend the lifespan of the manual transmission system.

7.3 Customizing Gear Ratios

Customizing gear ratios involves modifying the transmission to suit specific performance needs. This process requires understanding the function of each gear and how they interact. By adjusting the gear ratios, drivers can optimize acceleration, fuel efficiency, or towing capacity. However, customization demands precise calculations and expert knowledge to ensure proper alignment with the vehicle’s engine and drivetrain. Incorrect modifications can lead to poor performance or mechanical failure.

Troubleshooting Common Problems

Troubleshooting manual transmission issues involves identifying symptoms like fluid leaks, worn gears, or clutch wear. Inspecting components and addressing problems early prevents costly repairs.

8.1 Diagnosing Gear Shift Issues

Diagnosing gear shift issues in a manual transmission involves identifying symptoms like difficulty shifting, unusual noises, or leaking fluid. Inspect the clutch and synchronizers for wear, and check transmission fluid levels. Grinding or hesitation during shifts may indicate worn gears or misaligned components. Addressing these problems early can prevent further damage and ensure smooth operation. Regular inspection and maintenance are key to resolving gear shift issues effectively.

8.2 Identifying Noises and Vibrations

Noises and vibrations in a manual transmission can indicate underlying issues. Grinding or whining sounds may point to worn gears or bearings, while clunking noises could signal loose mounts or damaged synchronizers. Vibrations during operation often result from misaligned or imbalanced components. Regular inspection of gears, bearings, and mounts is crucial. Addressing these issues promptly helps prevent further damage and ensures smoother transmission performance over time.

8.3 Fixing Leaks and Seals

Transmission leaks often stem from damaged or worn seals, gaskets, or pan gaskets. Inspect the source of the leak and replace faulty components promptly. Clean the area thoroughly before installing new seals to ensure proper adhesion. Using the correct sealants and torque specifications is crucial. Addressing leaks early prevents fluid loss, corrosion, and potential damage to internal components. Regular maintenance can help avoid costly repairs.

Understanding manual transmission components is crucial for maintenance and performance. Regular inspections and timely repairs ensure longevity and efficiency, making it a cost-effective choice for drivers.

9.1 Summary of Key Points

The manual transmission parts diagram highlights essential components like gears, shafts, and synchronizers, which are vital for smooth operation. Understanding these elements helps in identifying common issues such as worn gears or leaks. Regular maintenance, including fluid checks and inspecting seals, ensures optimal performance. Addressing problems promptly, like clutch wear or bearing damage, prevents costly repairs. This knowledge empowers drivers to maintain their vehicles effectively, enhancing both reliability and longevity.

9.2 Final Thoughts on Manual Transmission Maintenance

Proactive maintenance is crucial for extending the life of a manual transmission. Regular inspections, timely repairs, and understanding component functions ensure smooth operation. Addressing issues like worn gears or leaks early prevents major overhauls. By staying informed and vigilant, drivers can enjoy improved performance, reduced costs, and a more reliable driving experience over the long term.